This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

section-c110228

PSA Nitrogen Generator

section-e990c87

TECHNICAL FACTS

| Flow Range | 1 Nm3/hr to 1500 Nm3/hr |

| Nitrogen Purity | 98% to 99.9999% |

| Dew Point | (-) 60°C to (-)80°C |

| Pressure | Direct delivery at 5 bar(g) pressure and higher pressures available with optional booster compressor |

Why PSA Nitrogen Generators?

PSA Nitrogen Gas Generators are suitable for high purity and high flow onsite gas generation requirements. They are the perfect replacement for bulk supplies and expensive and erratic gas supply from merchants in cylinders. Mature technology from our German Principals – CarboTech, since 1984, makes Pressure Swing Adsorption (PSA) the ideal choice for on site pure Nitrogen inert gas.

section-9a7fa90

PSA Nitrogen Generators are suitable for high purity Nitrogen requirements

section-9c9f8bf

section-9430abd

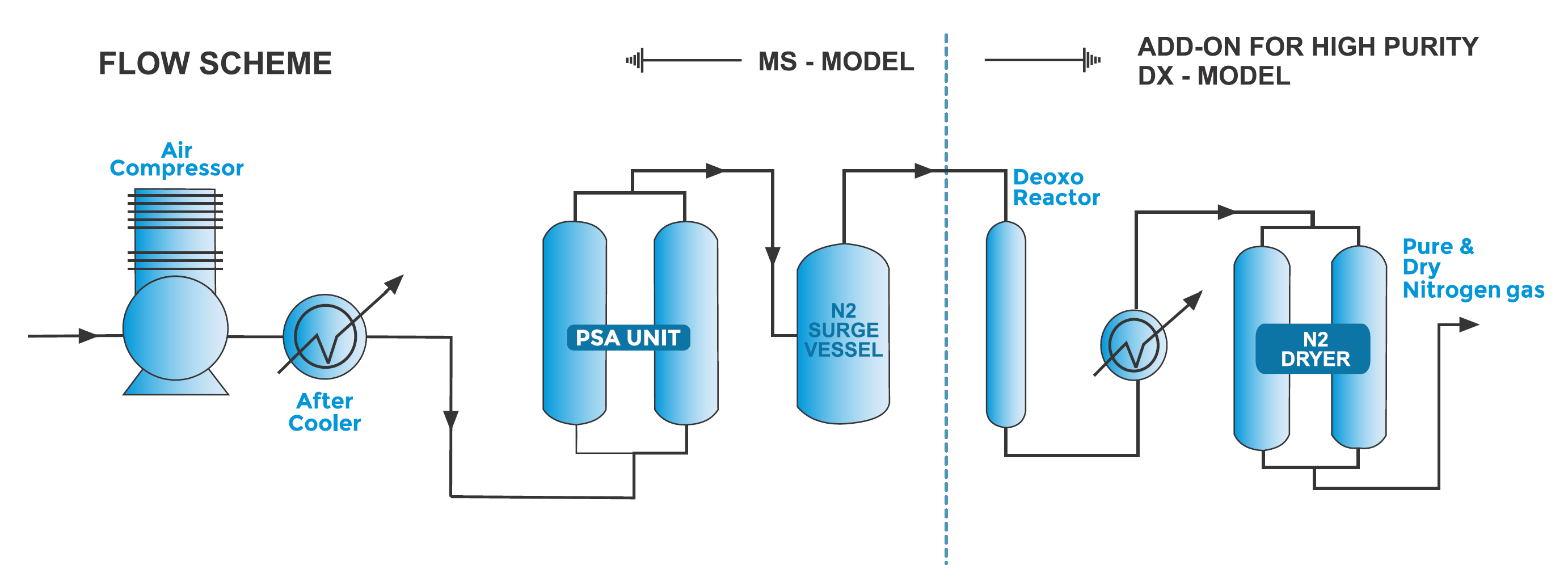

How PSA Nitrogen Generators Work?

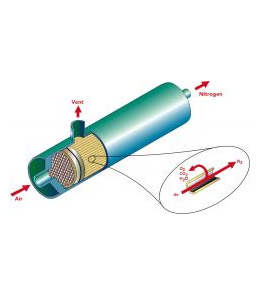

Atmospheric air comprises of 78% nitrogen and the PSA process utilizes CMS to extract this Nitrogen from air.

PSA process consists of 2 vessels filled with Carbon Molecular Sieves and Activated Alumina.

Clean compressed air is passed through one vessel and pure nitrogen comes out as product gas.

The exhaust gas (Oxygen) is vented to atmosphere. After a short duration of generation, upon saturation of the molecular sieve bed, the process switches Nitrogen generation to the other bed by automatic valves, while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure.

Thus 2-vessels keep cycling alternately in Nitrogen production and regeneration ensuring Nitrogen gas is continuously available to your process.

section-cf7122b

section-e1d2382

MODELS

| MS MODEL | |

|---|---|

| Oxygen | 0.1 to 5% |

| Hydrogen | Nil |

| Nitrogen | 95 to 99.9% |

| Dew Point | (-) 40°C to (-) 80°C |

| MS-H MODEL | |

|---|---|

| Oxygen | 1-ppm to 500-ppm O2 |

| Hydrogen | Nil |

| Nitrogen | 99.95% to 99.99999% |

| Dew Point | (-) 40°C to (-) 80°C |

| DX MODEL | |

|---|---|

| Oxygen | 1-ppm to 3-ppm (max) |

| Hydrogen | 0.5% or more |

| Nitrogen | Balance |

| Dew Point | (-) 40°C to (-) 80°C |

| COPPER-DX MODEL | |

|---|---|

| Oxygen | 1-ppm |

| Hydrogen | Nil |

| Nitrogen | 99.9999% |

| Dew Point | (-) 40°C to (-) 80°C |

section-b0c4038

FAQ’S

Several models are available to produce Nitrogen gas from 95% to 99.9999% purity. Oxygen level can be obtained as low as 1-ppm and Dew Point up to (-) 80°C.

Continuous supervision is not needed. Once started, it can be left unattended. Several instruments monitor and control the running of Gas generator automatically.

Yes, Nitrogen Generators are tailor made as per customer’s specifications of Nitrogen Purity and Nitrogen capacity.

Life of Molecular Sieves is around 10-years and in majority of the cases it lasts whole lifetime of the Gas generator. However, Molecular Sieves life is reduced by oil in air. Therefore, it is essential to use special pre-filters if lubricated air is used and filters should be replaced timely.

Yes. The Gas generator is supplied fully assembled on steel frames which are kept on floor. You simply connect power and the Gas generator becomes ready for start-up. We provide services of Engineer to supervise its installation and commissioning at site.

The noise level is less than 75dbA at 1-meter distance. A very effective silencer is provided in exhaust line. the total Gas Generator Package is “very silent”.

The “Maintenance Schedule” is given in our “Operation Manual”. The maintenance is limited to only replacement of filter elements and preventive maintenance in Air Compressor.

An On-line Oxygen Analyzer continuously monitors Nitrogen purity and shuts down the Gas generator automatically with alarm if purity drops below set limit.

Gas generator is designed to run continuously all 24-hours. But, if gas is not being consumed or consumption is low, pressure gradually builds up in Nitrogen Storage Tank. An automatic pressure switch stops the Gas generator. When pressure in the Nitrogen tank falls due to continuous gas consumption, the pressure switch automatically restarts the Gas generator.

The only expense in this Gas generator is of electricity for Air Compressor. Running cost is $0.05 (Rs. 3/-) per cubic meter of Nitrogen produced. This is very low as compared to cylinder Nitrogen cost of $0.35 (Rs. 20/-) per cubic meter. So, there is big cost saving when you install such Gas generator. Pay back period is only 1 to 2-years.

section-31e3e21

APPLICATIONS

Our On Site Nitrogen Gas Generators Are Widely Used Across Many Industries Including:

| Tyre filling (Automotive, Aircrafts, Dumpers, Mine Trucks) |

| Filling rubber tyres with Nitrogen greatly enhances the life of the tyre due to reduction in oxidation and by lower leakage thereby resulting in stable pressure maintenance |

| Fuel Tank Inerting (Petrochemical Complexes, Chemical Factories, Aircrafts) |

| Headspace in fuel tanks containing air may cause flammable mixture presence and flammability can be reduced by flushing and filling fuel tanks with Nitrogen |

| Autoclaves and Furnaces |

| Flammability and combustion risk can be reduced by using Nitrogen in autoclaves and furnaces |

| Blanketing for many industries (adhesives, pesticides, agro, pharmaceuticals) |

| Applications that require low oxygen presence or inert atmosphere are perfectly suited for Nitrogen gas |

| Metal processes (heat treatment, annealing, sintering) |

| Many processes for metals manufacturing require inert Nitrogen gas and a reducing gas such as Hydrogen for better product quality |

| Oil & Gas and Petrochemicals (Pigging, Blanketing, Headspace filling, Pipeline drying) |

| Handling of volatile chemicals and petrochemicals require presence of Nitrogen for safe handling of the process gas or liquid during various stages of handling |

| Laboratories (LCMS, Turbo Vap, GC, GCMS) |

| Large labs having centralized gas supply system benefit from onsite Nitrogen and Hydrogen gas generators for uninterrupted supply of gas |

| Offshore Platforms & FPSO |

| Due to handling of highly flammable crudes and volatile gases, Nitrogen is an absolute must for fire prevention |

| Oil cargo ships and oil tankers |

| Storage and transportation of oil and crudes is risky and requires Nitrogen for creating a fire-safe environment |

| Flex printing |

| For newer faster flex printing using eBeam machines, Nitrogen is a required utility for fast curing |

| Cables and CCV lines |

| For various processes in cable manufacturing industry, Nitrogen is a must for curing of material in high speed lines |

| Nitrogen in Food Packaging |

| Nitrogen has gained so much popularity in the Food packaging industry that it is now also used in the brewery or coffee industries. |