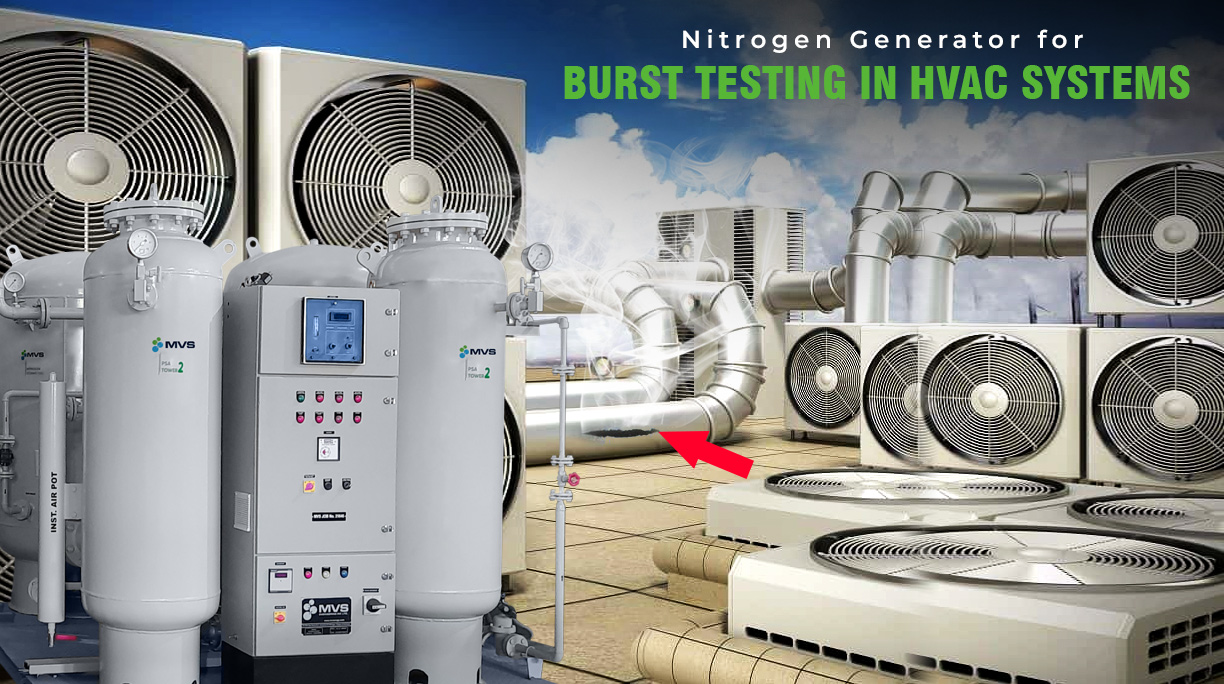

Nitrogen is a versatile gas that finds extensive use in various industrial applications, including burst testing of HVAC systems. HVAC (Heating, Ventilation, and Air Conditioning) systems are critical to the comfort and safety of building occupants. In this blog, we will discuss the benefits of using nitrogen for burst testing in HVAC systems and how it ensures the safety and performance of these systems.

The Process of Burst Testing

Burst testing is a process used to determine the maximum pressure that an HVAC system can withstand before failure. It is crucial to the safety and performance of these systems, as failure can lead to property damage, injury, and even death. Burst testing involves applying increasing levels of pressure to the HVAC system until it fails. The results of this test determine the system’s maximum pressure capacity and identify any design or manufacturing flaws that may compromise its safety and performance.

The Role of Nitrogen in Burst Testing

Nitrogen is utilised in burst testing to assure the precision and safety of the test. Nitrogen is an inert gas that does not react with the HVAC system’s components, preventing contamination and damage. Using nitrogen in burst testing has various advantages, such as better precision and safety, decreased chance of damage to the system, and improved dependability of the test findings.

Industries that Use Nitrogen for Burst Testing in HVAC Systems

Other gases, such as air and helium, are also used in burst testing. However, these gases have several disadvantages compared to nitrogen. Air contains moisture and other contaminants that can affect the accuracy of the test and damage the system. Helium is more expensive than nitrogen and can be challenging to obtain in large quantities. Nitrogen is the most widely used gas in burst testing due to its affordability, availability, and safety.

Several businesses utilise nitrogen for burst testing in HVAC systems. The manufacturing business employs burst testing to assure the quality and safety of the HVAC systems they make, while the construction industry uses burst testing to check the integrity of these systems during installation. The HVAC industry employs burst testing to verify the safety and operation of HVAC systems in residential, commercial, and industrial facilities.

Also Read

-

-

15 NM³/HR NITROGEN PLANT OPERATING AT HEAT TREATMENT COMPANY IN DELHI-NCR

-

-

150 NM³/Hr Nitrogen Plant Operating At Leading Chemical Company In Western India

Conclusion

In conclusion, employing nitrogen for burst testing in HVAC systems has various advantages that increase the safety and performance of these systems. Nitrogen guarantees the precision and safety of the test, lowers the danger of harm to the system, and increases the dependability of the test findings. Its usage in burst testing is common in numerous sectors, including manufacturing, construction, and HVAC, and it will continue to play an important role in preserving the safety and performance of HVAC systems in the future.