This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

section-c110228

Pure Hydrogen Plant

section-e990c87

Onsite Generation of Pure Hydrogen

Water Electrolysis

We are the leaders in water electrolysis hydrogen gas plants in India and carry a reference list of more than a hundred satisfied customers in India and overseas. We utilize bipolar high-pressure, high-purity electrolysis for delivering gas to the customer process. This is one of the simplest and fastest technology for hydrogen production and only requires power and deionized water for hydrogen production.

We are the leaders in water electrolysis hydrogen gas plants in India and carry a reference list of more than a hundred satisfied customers in India and overseas. We utilize bipolar high-pressure, high-purity electrolysis for delivering gas to the customer process. This is one of the simplest and fastest technology for hydrogen production and only requires power and deionized water for hydrogen production.Hydrocarbon – Reforming Technology

Using methanol, naphtha and natural gas is suitable for high flow and high purity production of hydrogen. We have collaborations with European and North American leaders for hydrogen production using these hydrocarbons and offer their cutting edge technology to customers in India. Hydrogen production using hydrocarbons is very cost effective and offers excellent ROI.

Using methanol, naphtha and natural gas is suitable for high flow and high purity production of hydrogen. We have collaborations with European and North American leaders for hydrogen production using these hydrocarbons and offer their cutting edge technology to customers in India. Hydrogen production using hydrocarbons is very cost effective and offers excellent ROI.Stirling Cryogenics

section-6ac7ac4

Specifications and advantages

The functionality and specifications of MVS water electrolysis hydrogen plant and the advantages include:

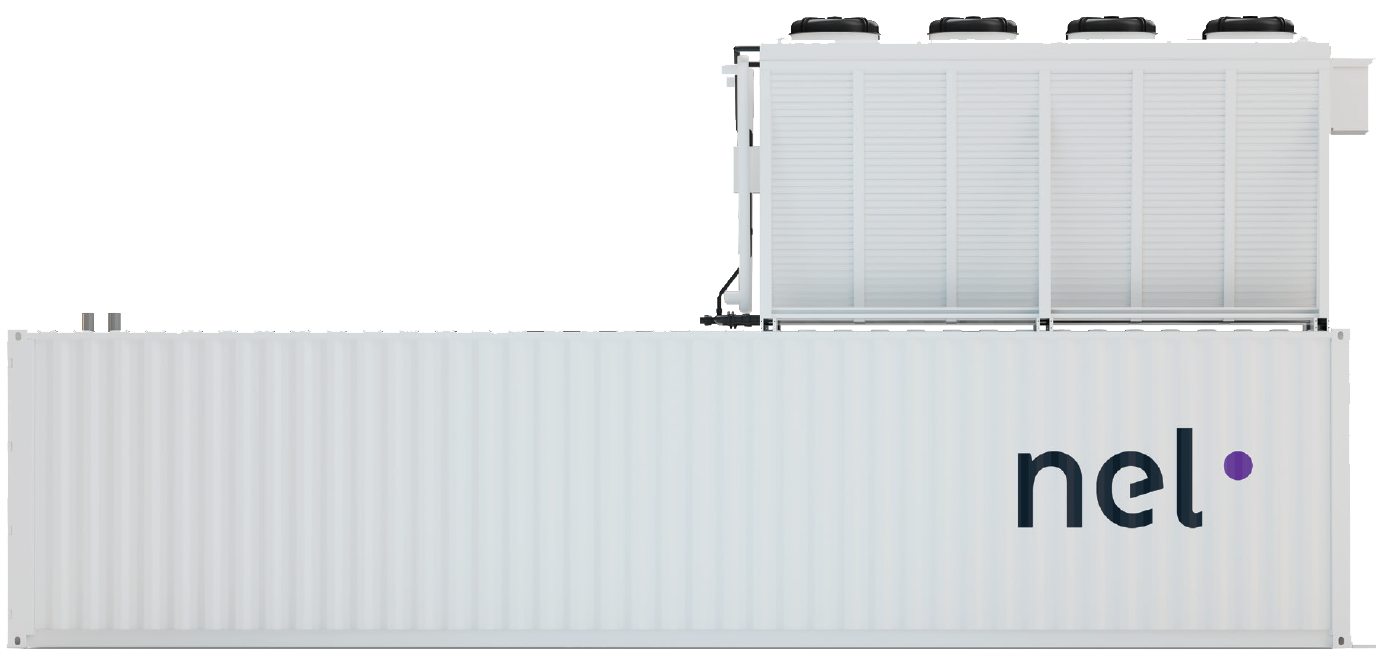

- Skid mounted construction for bipolar systems and panel construction for PEM generators from Proton NEL

- Ease of installation – system handed over in under a week

- Fully automatic operation by PLC control

- Systems can be designed in load following or tank filling mode

- Efficient production by using power efficiently thereby keeping your cost of production as low as possible

- Best in class instrumentation and code adherence for Hydrogen safety

- High pressures up to 700 bar(g) using booster compressor available as add-ons

- MVS Hydrogen Gas Generator Built for Indian climatic conditions

HOW IT WORKS

HOW IT WORKS

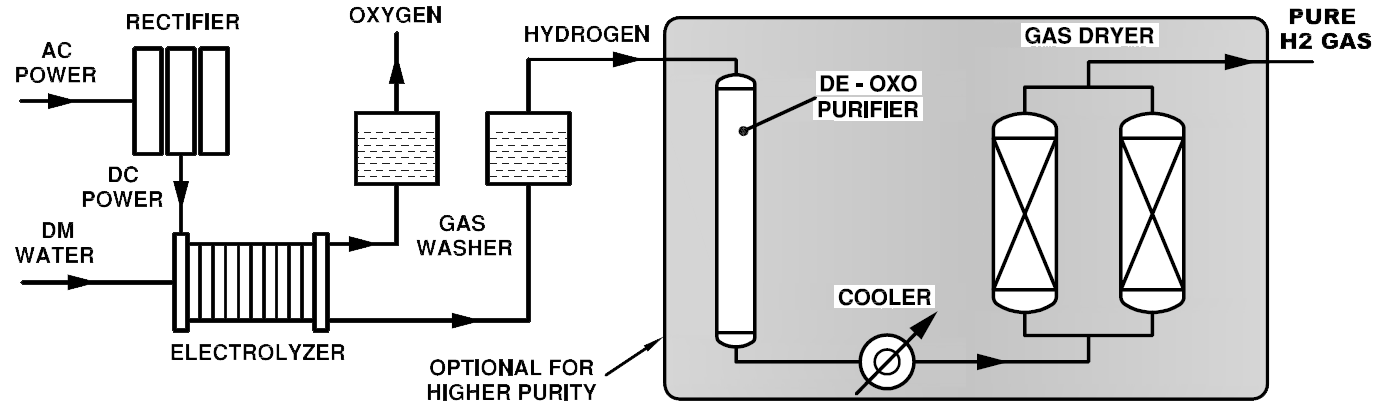

Bipolar Technology – Using Alkaline electrolyte

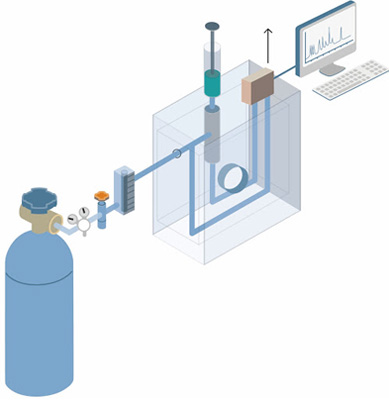

Our Electrolyzer is of Bipolar design where high purity DM water is broken to H2 and O2 using DC power supplied by rectifier. Hydrogen is evolved on cathode side of cells and oxygen on anodes of cells. The design makes our Electrolyzer unit very compact in size. This is a specially developed cell unit producing gases at high pressure 15 Bar directly. So, no Hydrogen compressor is needed for medium Hydrogen pressure requirements.

HOW IT WORKS 1

Proton Exchange Membrane (PEM)

The electrolyser is based upon proton exchange membrane technology. Hydrogen gas is generated at the cathode at customer convenient pressures. Oxygen gas is produced at the anode at pressures close to ambient. The near infinite bubble point of the membrane prevents oxygen from entering the hydrogen stream. The full differential pressure design provides for safe, simple operation.

The electrolyser is based upon proton exchange membrane technology. Hydrogen gas is generated at the cathode at customer convenient pressures. Oxygen gas is produced at the anode at pressures close to ambient. The near infinite bubble point of the membrane prevents oxygen from entering the hydrogen stream. The full differential pressure design provides for safe, simple operation.

MODELS

MODELS

| MVS Bipolar Electrolyzer | |

|---|---|

| Hydrogen production | 5 to 500 Nm3/hr – single stream |

| Hydrogen purity | Low purity option – 99.5% High purity option – 99.9995% |

| Hydrogen dew point | Low purity option – saturated High purity option – (-) 65°C or lower |

| Hydrogen delivery pressure | 15 bar |

| Oxygen | Recovery possible at added cost |

| Electrolyte | Alkali – Potassium Hydroxide or KOH |

| Power requirement | 4.8 kw/Nm3-H2 |

| Utilities required from customer | Power, Deionized Water, Cooling Water |

| NEL PEM S-Series | |

|---|---|

| Hydrogen production | 0.25 to 1 Nm3/hr |

| Hydrogen purity | 99.9995% H2 |

| Hydrogen dew point | (-) 65°C |

| Hydrogen delivery pressure | 15 bar(g) |

| Oxygen | Recovery not possible |

| Electrolyte | PEM – Solid Electrolyte Membrane |

| Power requirement | 6.7 kw/Nm3-H2 |

| Utilities required from customer | Power, Deionized Water |

| NEL PEM H-Series | |

|---|---|

| Hydrogen production | 2 to 6 Nm3/hr |

| Hydrogen purity | 99.9995% H2 |

| Hydrogen dew point | (-) 65°C |

| Hydrogen delivery pressure | 15 bar(g) or 30 bar(g) optional |

| Oxygen | Recovery not possible |

| Electrolyte | PEM – Solid Electrolyte Membrane |

| Power requirement | 6.8 – 7.3 kw/Nm3-H2 |

| Utilities required from customer | Power, Deionized Water, Cooling Water |

| NEL PEM C-Series | |

|---|---|

| Hydrogen production | 10 to 30 Nm3/hr |

| Hydrogen purity | 99.9998% H2 |

| Hydrogen dew point | (-) 72°C |

| Hydrogen delivery pressure | 30 bar(g) |

| Oxygen | Recovery not possible |

| Electrolyte | PEM – Solid Electrolyte Membrane |

| Power requirement | 5.8 – 6.2 kw/Nm3-H2 |

| Utilities required from customer | Power, Deionized Water, Cooling Water |

| NEL PEM MC-Series | |

|---|---|

| Hydrogen production | 250 or 500 Nm3/hr |

| Hydrogen purity | 99.95% H2 or 99.9995% high purity option |

| Hydrogen dew point | H2O < 5 ppm |

| Hydrogen delivery pressure | 30 bar(g) |

| Oxygen | Recovery not possible |

| Electrolyte | PEM – Solid Electrolyte Membrane |

| Power requirement | 1.25 MW or 2.5 MW |

| Utilities required from customer | Power, Deionized Water, Cooling Water |

Cryomech – 10 to 240 Liters/Day

Hydrocarbon – Reforming Technology

section-0e8b194

The production of pure hydrogen (up to 99.9999%) is essential for a number of industries in very different fields. In association with our European principals having more than 80 realized hydrogen production plants worldwide, we are capable to provide highly cost-effective, customized and proven solutions for hydrogen generation plants based on natural gas, on LPG, naphtha, methanol and other hydrocarbon feeds.

The production of pure hydrogen (up to 99.9999%) is essential for a number of industries in very different fields. In association with our European principals having more than 80 realized hydrogen production plants worldwide, we are capable to provide highly cost-effective, customized and proven solutions for hydrogen generation plants based on natural gas, on LPG, naphtha, methanol and other hydrocarbon feeds.

Steam Reformer – Natural Gas / LPG / Naphtha

High purity hydrogen is produced by steam reforming of a hydrocarbon combined with a PSA purification step. The feed is mixed with a split stream of hydrogen and then preheated in the heat exchanger prior to passing a sulphur removal. The feed is then mixed with superheated steam. Whilst passing the catalyst in the reformer tubes, the mixture of water vapour and feed is converted into a syngas consisting of H2, CO, CO2, H2O and CH4.

The hot syngas passes the heat exchanger in which the main part of sensible heat is utilised, thus adjusting the temperature of the syngas for the subsequent CO-shift. In the cooler following the CO-shift, the syngas is cooled to ambient temperatures, whilst simultaneously water vapour is condensed and subsequently separated. The syngas further passes through the molecular sieve PSA purification unit where hydrogen is isolated to the specified purity.

The reformer is fired by a high-velocity burner which burns fuel and tail gas. Tailgas produced in the PSA purification unit is buffered in the tail gas buffer tank. The hot flue gases of the reformer pass the waste heat boiler prior to being used to superheat feed/steam mixture and to preheat the feed in the heat exchangers.

Methanol Reforming

High purity hydrogen is produced by methanol reforming combined with a PSA purification step.

A mixture of methanol and DM water is vapourised in heat exchangers. After passing through the heated catalyst, the methanol/water vapour mixture is converted into a syngas consisting of H2, CO, CO2, CH4 and water vapour. In a cooler, the syngas is cooled to ambient temperatures, whilst simultaneously water vapour is condensed and recycled to the storage tank. The syngas now passes the molecular sieve PSA purification unit, where the hydrogen is isolated to the specified purity. The tail gas from the PSA purification unit is sent to the buffer tank. From the buffer tank, the tail gas is used as fuel for the required process heat.

The required heat for the process can be supplied either by our Principal’s unique circulation of hot inert gas or by a thermal oil system.

Using the circulation of inert gas instead of thermal oil as heat transfer fluid for heating, the reformer makes a thermal oil system obsolete and avoids all costs and problems of handling thermal oil.

A thermal oil heated plant may be more feasible for installations in an environment where thermal oil is already available or in very large MeOH based reforming plants (more than apx. 2000 Nm³/h H2) as the physical equipment size of the circulated inert gas-based plant grows disproportionally.

MODELS

MODELS

| Steam Methane Reformer | |

|---|---|

| Feedstock | Natural Gas (Methane), LPG, Naphtha |

| Capacity Range | 200 – 6,500 Nm3/hr single reformer 6,500 – 13,000 Nm3/hr twin reformer |

| Hydrogen purity | Typically 99.999% by vol. |

| Hydrogen delivery pressure | 15 bar(g) |

| Operation | Automatic, PLC Controlled |

| Utilities | For the production of 1,000 Nm3/hr H2 from natural gas the following utilities are required:

|

| By-product | Export steam, if required by customer |

| Methanol Reforming | |

|---|---|

| Feedstock | Methanol (e.g. British Standard BS 506) |

| Capacity Range | 200 – 5,000+ Nm3/hr |

| Hydrogen purity | Typically 99.999% by vol. |

| Hydrogen delivery pressure | 15 bar(g) |

| Operation | Automatic, PLC Controlled |

| Utilities | For the production of 1,000 Nm3/hr H2 from methanol the following utilities are required:

|

| By-product | Export steam, if required by customer |

section-b0c4038

FAQ’S

Hydrogen gas at very high purity is delivered from all our systems. We are able to supply hydrogen as pure as 2 ppm Oxygen impurity content, thereby delivering 99.9998% pure hydrogen

Continuous supervision is not needed. Once started, it can be left unattended. The systems are fully automated and PLC controlled. Periodic maintenance can be done easily by customer’s own engineers.

Yes, we offer a variety of technologies and our Hydrogen Generators can be tailor made as per customer’s specifications.

Both technologies have their merits. PEM is very suitable for compact installations and safe area installations. Alkaline technology is very suitable for large industrial needs with continuous operation. There is a difference in investment and we help our customers understand the upfront difference in investment and also the total cost of ownership to help make an informed decision.

Yes. All our generators are skid mounted or panel mounted and installation at site takes a few days (water electrolysis) and a few weeks (hydrocarbon reforming). We provide installation supervision and commissioning services. During commissioning of equipment, customer’s operators and engineers are trained in maintenance of plant.

The noise level is less than 75dbA at 1-meter distance. The total Gas Generator Package is “very silent”.

The “Maintenance Schedule” is given in our “Operation Manual”. Periodic preventive maintenance ranges from checks and changes every few months to some operations every few years.

section-31e3e21

APPLICATIONS

| Power plants – TG cooling |

| Hydrogen gas is used for cooling of large Turbine Generators at thermal power plants |

| Additive Manufacturing |

| Many reactions for manufacturing of additives require hydrogen for their process |

| Ammonia and Fertilizer |

| Hydrogen is consumed in very large scale for production of ammonia and fertilizers |

| Chemical Industry |

| Chemical industry uses hydrogen for their reactions in many complex processes and reliable uninterrupted supply of hydrogen is critical |

| Crystal Growth (CVD) |

| Ultra high purity hydrogen is required for crystal growth and lab grown diamonds by using the Chemical Vapour deposition (CVD) process |

| Gas Merchants |

| Gas merchants that require to sell technical and commercial grade hydrogen use on-site production of hydrogen |

| Foodstuff applications |

| Hydrogenation of fats and oils is necessary for commercial foodstuff production |

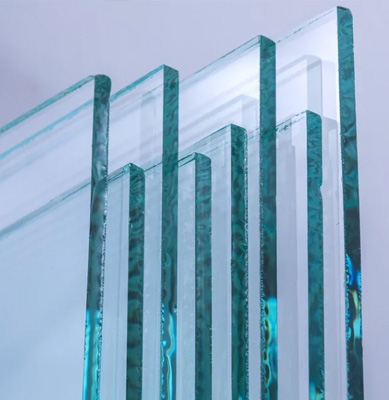

| Float Glass |

| Float glass industry requires continuous supply of pure hydrogen for tin bath application |

Polysilicon manufacturing | |

| Hydrogen is a critical raw material for polysilicon manufacturing that supports the solar industry |

| Refinery and Petrochemicals |

| Hydrogen is used in very large quantities for catalyst reduction and also for R&D processes at major oil & gas companies |

| Labs – Gas Chromatography |

| Laboratories require a stable source of hydrogen for their gas chromatographs. Large labs prefer to have a single source of hydrogen to avoid variability in their test results |

Semiconductor | |

| Hydrogen is a critical raw material for semiconductor manufacturing |

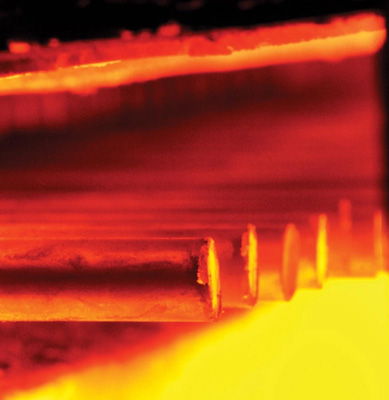

| Steel – Metal heat treatment |

| Hydrogen is widely used in heat treatment furnaces and for applications such as sintering and annealing which yields superior surface finish |

| Thermal processing |

| Hydrogen is increasingly being used in high technology thermal processing applications |