section-e990c87

Biogas Upgrading Solutions by MVS Engineering

At MVS Engineering Pvt. Ltd, we specialize in transforming raw biogas into high purity biomethane with advanced technology and precision engineering. Our System are designed exclusively for biogas purification, utilizing state-of-the-art membrane technology to ensure maximum efficiency and reliability.We optimize biogas upgrading for various industries, including agriculture, waste management, and industrial applications. Our solutions guarantee superior purification maximizing product recovery, and enhancing sustainability.

HOW IT WORKS

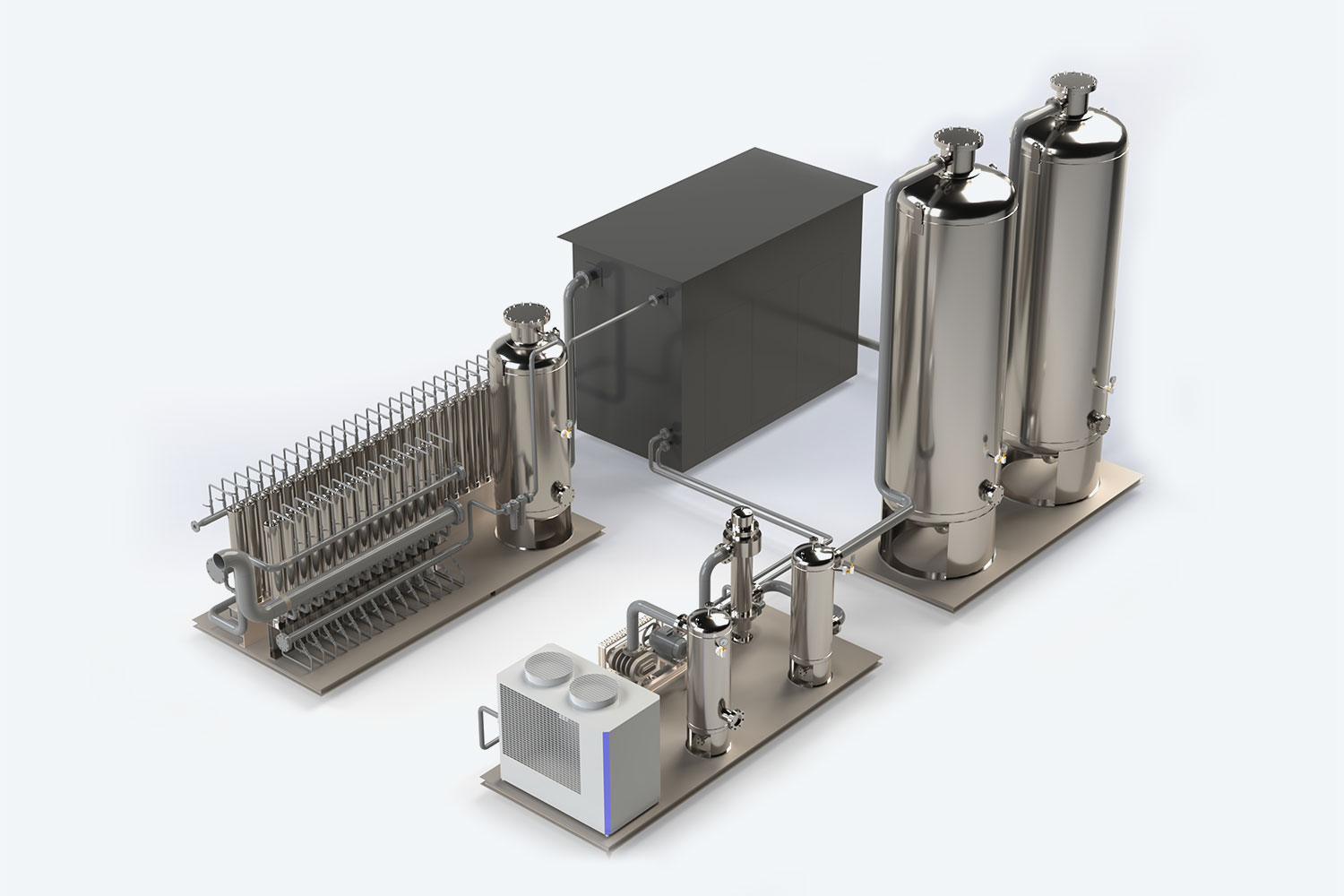

A high-efficiency biogas upgrading system designed for maximum methane recovery and enhanced sustainability. Our membrane separation technology ensures optimal purification. The 3D model below visually represents its innovative design and functionality.

section-5e5ec08

Process Steps

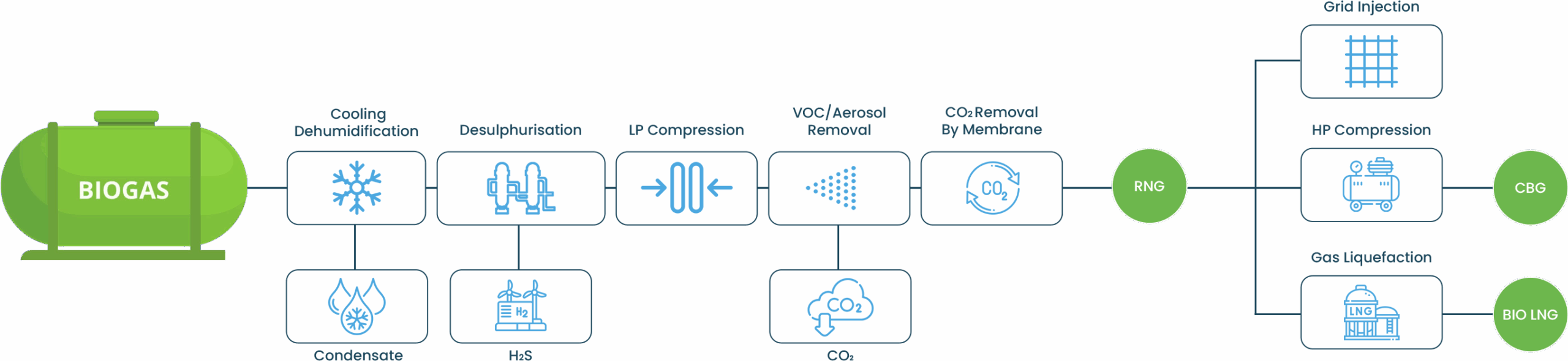

Dehumidification and Desulphurization:

Raw biogas from the digester undergoes initial treatment to remove moisture and hydrogen sulphide preventing corrosion and ensuring downstream equipment protection.

Compression and Condensable Removal:

The treated biogas is compressed to optimal pressure, enabling the removal of water vapors and condensable impurities.

Advanced Dehydration:

Further moisture reduction ensures the biogas meets the low dew point requirements of the downstream membrane modules.

Volatile Organic Compound Removal:

Any residual volatile organic compounds (VOCs), which could affect membrane performance, are eliminated to maintain gas purity.

Carbon Dioxide Removal:

Using high-efficiency membrane separation technology, carbon dioxide is selectively removed, yielding upgraded biomethane with Purity above 97% and Recovery up to 99%.

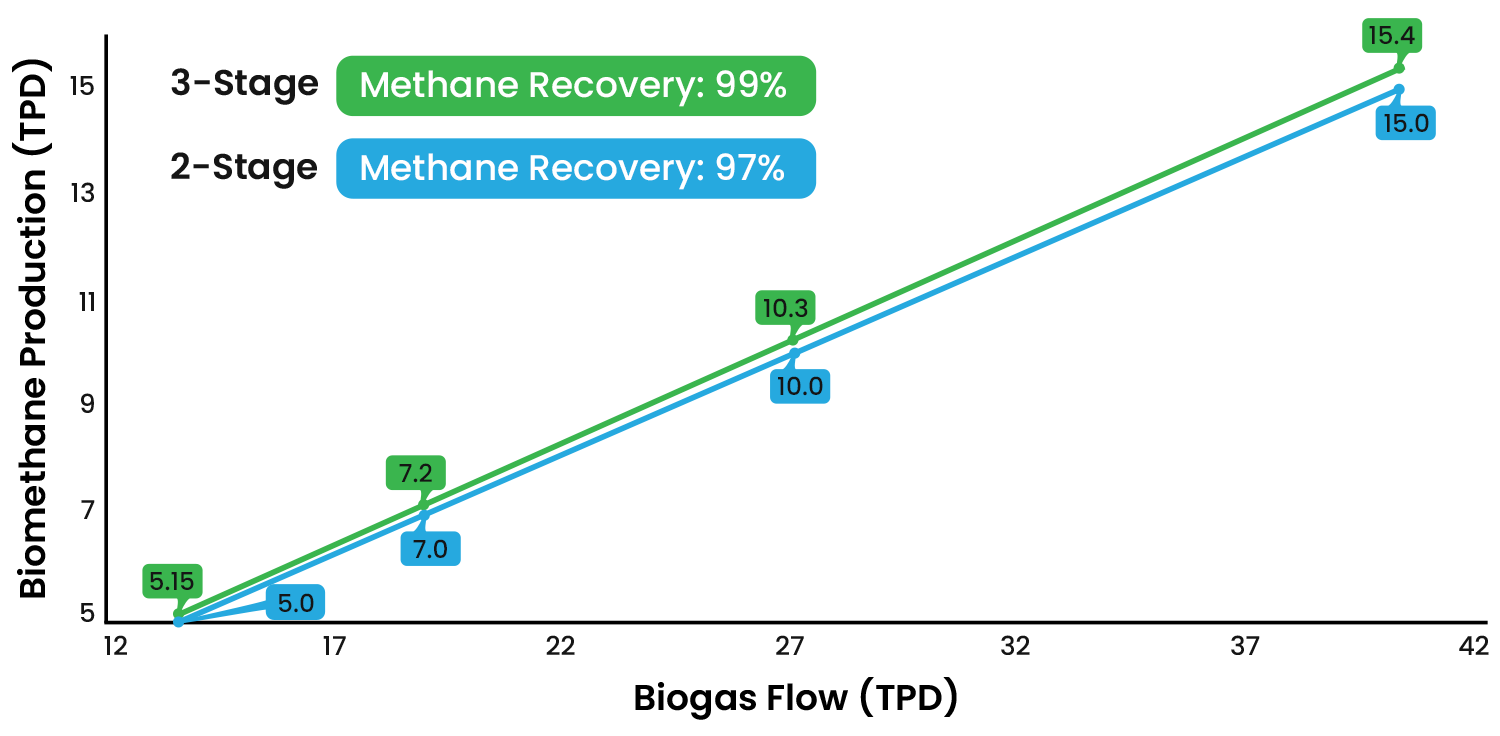

Graph

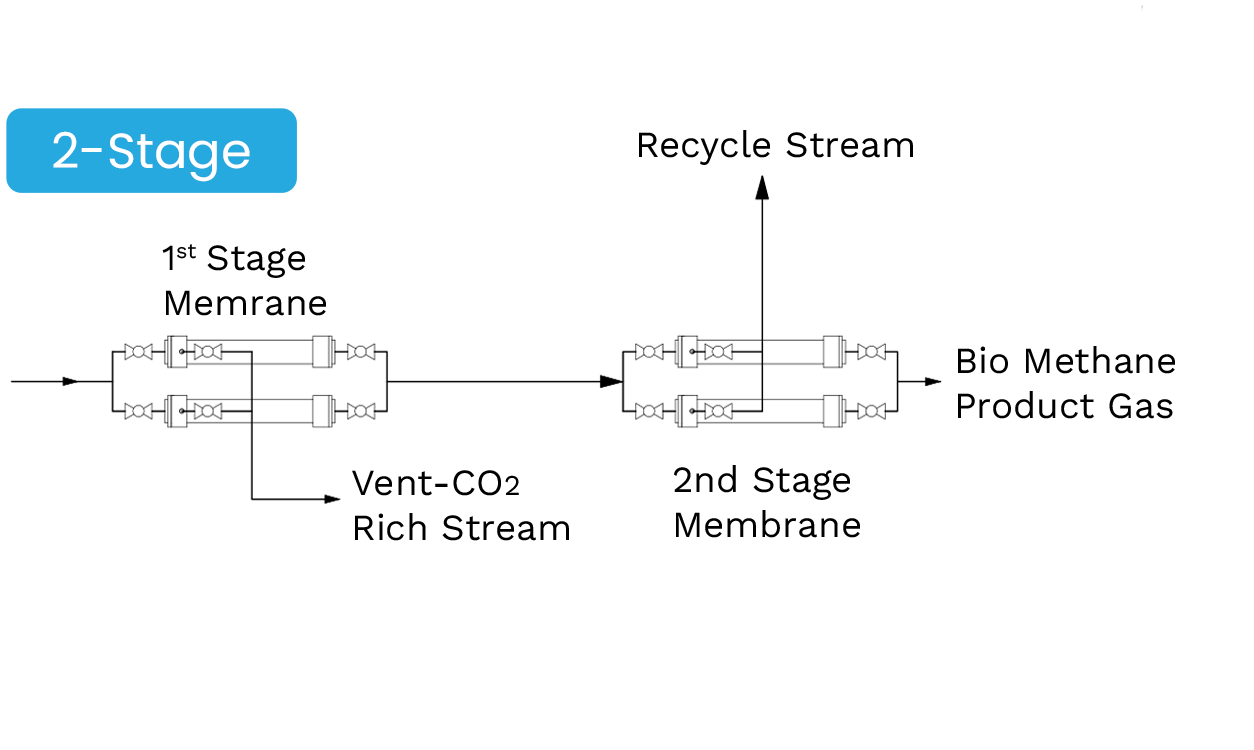

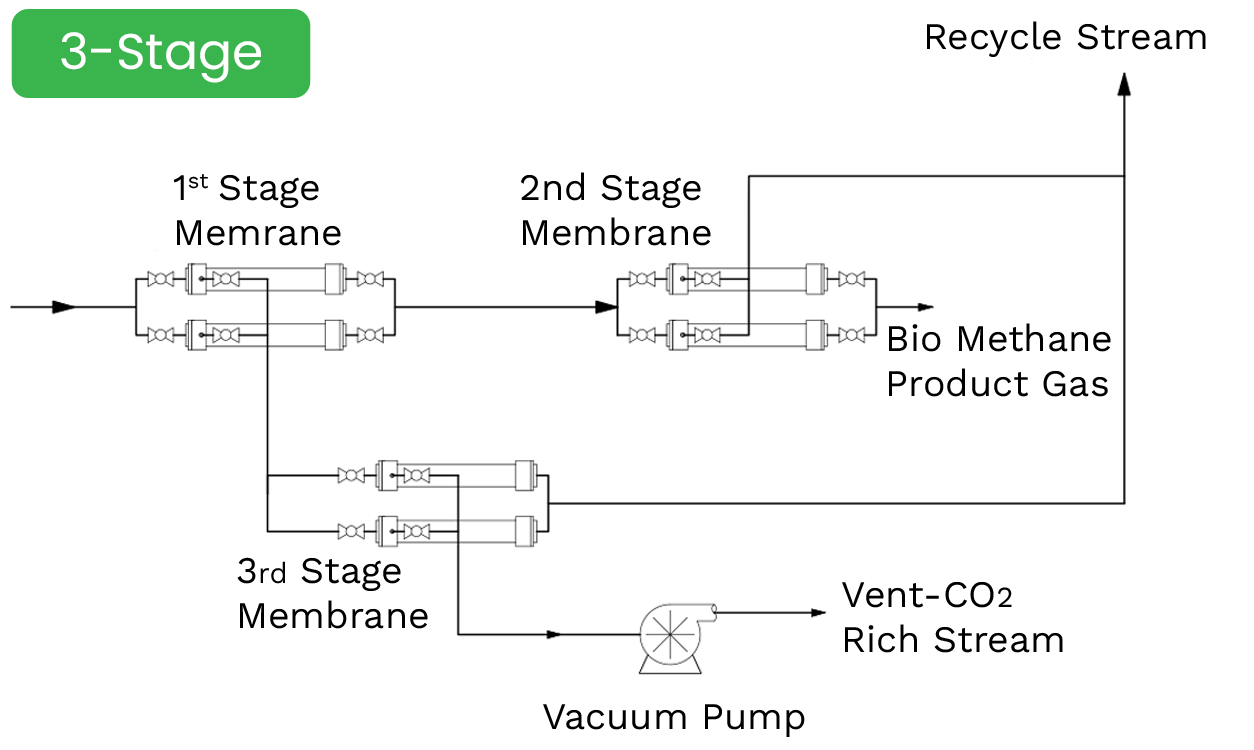

2-stage vs 3-stage Membrane Based Upgradation

A two stage membrane based biogas upgradation can offer a methane recovery of >97%, however a three stage membrane based biogas upgradation can offer a higher recovery of >99%.

Key Advantages

Advantages

Performance & Efficiency

Advanced Separation

High-efficiency membranes for CO₂ removal and high methane yield

Proven Performance

Reliable operation with consistently high methane recovery

Flexible Operation

Capable of handling variable input gas flows without performance loss

Safety & Environmental Impact

Safe Operations

No need for hazardous chemicals

No Secondary Waste

No generation of liquid or solid waste streams

Low Footprint

Requires less physical space compared to conventional systems

Scalability & Integration

Modular Design

Easily scalable and compatible with existing infrastructure

Easy Scale-Up

Suitable for both small and large installations

Redundancy and Flexibility

Customizable membrane configurations for operational flexibility

Reliability & Maintenance

No Moving Parts

Less wear and tear, reducing the likelihood of mechanical failure

Low Maintenance Requirements

Simplified maintenance through design redundancy & intelligent monitoring systems

Low Energy Consumption

Consumes less energy than traditional biogas upgrading methods