Nitrogen in liquid or gaseous form is widely needed in many industries. So, MVS Engineering Pvt. Ltd offers onsite nitrogen generators to fulfill these requirements. Unique nitrogen plants with special membrane systems are now available from this company, which are run by electricity. Due to the effectiveness of membranes, MVS Engineering is now counted among the best membrane manufacturers in India. All users speak highly of nitrogen membrane generators, due to various facilities integrated into these machines.

Beneficial aspects of nitrogen membrane generators

MVS Engineering applies the American technologies of MEDAL – Air Liquide to manufacture hollow fibrous membranes. These membrane generators can also be used for producing oxygen and hydrogen, apart from nitrogen from the air. However, nitrogen is the notable product of this generator, as designed by membrane manufacturers in India.

MVS Engineering applies the American technologies of MEDAL – Air Liquide to manufacture hollow fibrous membranes. These membrane generators can also be used for producing oxygen and hydrogen, apart from nitrogen from the air. However, nitrogen is the notable product of this generator, as designed by membrane manufacturers in India.

Highly durable membranes – Membranes are made of polymer blend fibers of great strength. These hollow fibers are arranged in an advanced design to form the membranes, following the Air Liquide technology. It is seen that these membranes last up to 20 years and hardly need replacements in the lifetime of most nitrogen generators. Moreover, air is freed from oil and dust particles before reaching the membranes of nitrogen generators, to ensure better durability of these membranes.

No need for extra manpower – Anyone in the client’s company can take up the job of switching on and off the nitrogen membrane generator. No professional training or technical knowledge is required for this job. The generator is fully automated, and all its components start functioning once it is switched on. Hence, nitrogen production starts within 10 minutes of starting the generator. Atmospheric air is automatically sucked in and passed through the compressor and cooler, to make it ready for passing through membranes.

Optimized size of generator – MVS Engineering can customize a nitrogen membrane generator according to the needs of the client. However, experts of this company study the volume of nitrogen needed by the client and the space allotted for installing the generator before optimizing its compact size. The required purity level of nitrogen is another factor considered by membrane manufacturers in India for the optimization of a nitrogen membrane generator.

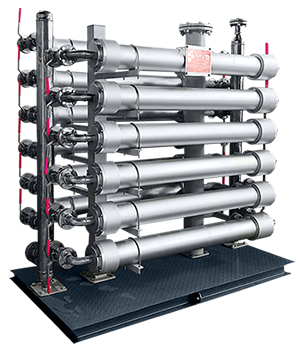

Simple installation process – MVS Engineering sends certified engineers to supervise the installation and commissioning of nitrogen membrane generators. Fibrous membranes, air cooler, air compressor, and filters are all mounted on steel frames that rest on the floor. After assembling all parts accurately, the generator is connected to the power supply for running the machine.

Assurance of high purity level – A nitrogen membrane generator can produce very pure and dry nitrogen gas, whose purity level varies between 95% and 99.5%. A specific purity level can be set according to the demand of a client. If this purity level drops below this range, the production automatically stops with an alarm. If any customer wants to set a higher purity level, the flow rate of nitrogen gas will automatically decrease.

Also Read

Therefore, MVS Engineering is now counted among the leading membrane manufacturers in India, due to all these above-mentioned benefits associated with this membrane generator.